Teaching Manufacturing Processes – zyBooks Guide

Practical strategies for improving student success with interactive learning

The Evidence for Interactive Learning

Peer-reviewed research in engineering courses using zyBooks has documented statistically significant improvements when activities are assigned for grades. A study of engineering courses found that the percentage of students receiving A’s, B’s, and C’s increased from 45% to 57%. While these results depended on course implementation; the data showed a clear difference between courses that required the completion of activities for credit and those that didn’t.

The zyBook version of Mikell Groover’s Fundamentals of Modern Manufacturing applies this approach to manufacturing processes through hundreds of interactive activities including animations, learning questions, and auto-graded problems.

This guide shares feedback from instructors who reviewed the material and implementation strategies from the zyBook development team for instructors to achieve similar outcome improvements. These approaches address common challenges in teaching the course, from equipment limitations to student comprehension of dynamic processes.

The Pre-Class Foundation: Setting Students Up for Success

The Critical 5% Rule

zyBooks’ peer-reviewed research points to one essential requirement: assign zyBook activities for a minimum 5% of the final grade. This threshold makes the difference between student engagement and non-use.

The numbers tell the story. Without a grade incentive, students spent an average of 83 minutes in the zyBook per semester. When activities counted for 5% of the grade, average engagement time increased to 410 minutes. The zyBooks research found that without grade allocation, even the best students rarely complete the activities. The 5% minimum provides sufficient incentive while remaining a manageable portion of the overall grade.

Engagement Data

- Without grade incentive: 83 minutes average/semester

- With 5% grade allocation: 410 minutes average/semester

- Documented outcome: 22% reduction in D/F rates

Source: zyBooks Research

What to Assign Before Each Class

Pre-class assignments should include three components:

- Reading sections with embedded animations – Introduces concepts with visual support

- Participation activities – Auto-graded questions that check comprehension

The development team notes that manufacturing processes are particularly difficult to understand from static images alone. Traditional textbook figures show start and end states but not the continuous transformation between them. Animations allow students to observe these transitions, pause at critical moments, and replay sections as needed.

Using Animations to Show Manufacturing Processes

When access to machinery has been difficult at some universities, professors have relied on videos to demonstrate machine processes. Even for those with access to manufacturing equipment, viewing the internal mechanics is not possible. zyBooks uses animations to walk students through the steps of manufacturing processes.

The animations show cross-sections of equipment during operation, revealing polymer flow patterns, temperature gradients, and pressure changes. Students can observe the screw rotation, melting progression, and mixing action that occur inside the steel barrel—processes that remain hidden even during hands-on equipment demonstrations.

Proactive Insights Into Student Struggle

The zyBook dashboard provides data on student engagement and performance. A brief review before class reveals:

- Which students haven’t completed assignments

- Problems with low first-attempt success rates

- Sections requiring excessive time

- Frequently replayed animations

This information helps identify concepts that need additional classroom attention. For example, if many students replay the sheet metal forming animation multiple times, it suggests confusion about the process that should be addressed in lecture.

Transforming Classroom Time: From Passive to Active

Building on Pre-Class Preparation

When students complete readings and animations before class, they arrive with basic knowledge about the content in place. This preparation allows class time to focus on applications, problem-solving, and design considerations rather than introducing fundamental concepts.

The development team has observed that pre-class preparation allows instructors to use classroom time more effectively, such as diving into solving problems. Instead, for example, of explaining extruder components for 30 minutes, instructors could jump into showing students how to calculate screw designs or discuss material selection for a specific application. It also creates the opportunity for richer classroom discussions.

The Group Challenge Method

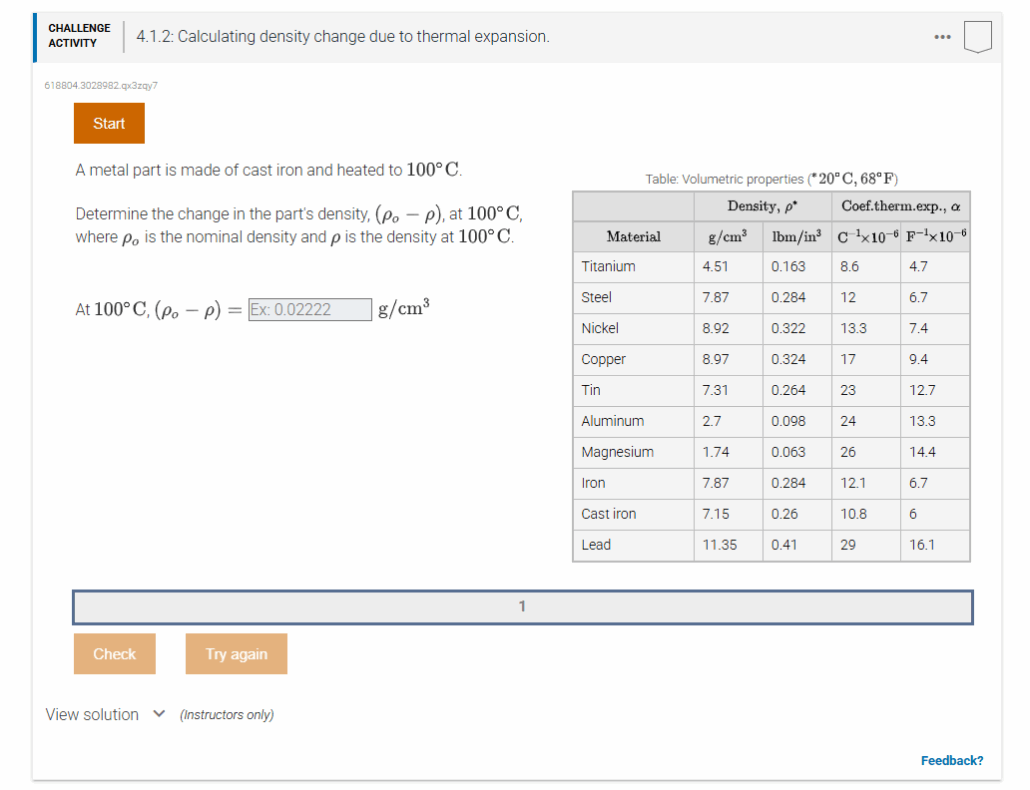

The zyBook’s randomization feature supports collaborative learning. Challenge activities can be used as traditional homework, with auto-grading and immediate feedback. But another approach we suggest involves dividing the class into small groups and assigning the same challenge activity to each group. The system automatically provides different numerical values to each group.

This randomization serves several purposes. Students must understand the problem-solving methodology since they cannot copy answers from other groups. Groups can then compare solutions, leading to discussions about the effectiveness of different approaches. Students learn that engineering problems often have multiple valid solution paths.

The development team reports that this technique promotes peer learning. Students explain concepts to each other and share problem-solving strategies. The discussions that emerge often reveal conceptual gaps that might otherwise go unnoticed.

Group Challenge Implementation

- Form groups of up to 6 students

- Assign the same challenge activity to all groups (zyBooks system provides different values automatically)

- Allow 15-20 minutes for problem-solving

- Groups present their approaches

- Discuss how different process parameters affect the fabrication time, cost, quality, etc.

Addressing Common Misconceptions

The development team identified common student misconceptions through years of teaching experience. The zyBook includes specific features to address these misunderstandings.

For example, many students believe casting can only produce solid shapes. The zyBook animations demonstrate how cores create internal cavities, using examples from everyday products to industrial components.

Interactive questions include common wrong answers that reveal these misconceptions. When students select incorrect options, they receive explanations about why their answer was wrong. When they select the correct answer, they also receive feedback that reinforces why that answer is correct. This immediate feedback helps correct common student misconceptions in real-time.

Time Allocation Benefits

Instructors who teach manufacturing report that the use of auto-graded problems frees substantial time for other activities. This time can be redirected toward complex design projects, case studies, and detailed feedback on student work—skills that are harder to assess but more valuable for engineering practice.

Assessment That Drives Learning

The Hybrid Homework Approach

The subject matter experts at zyBooks recommend combining zyBook activities with traditional assignments:

50% zyBook challenge activities:

- Auto-graded with immediate feedback

- Multiple attempts with new values

- Solution explanations after incorrect attempts

50% traditional design problems:

- Multi-step applications

- Open-ended design scenarios

- Detailed instructor feedback

This combination uses each assessment type for its strengths. The zyBook handles routine practice and provides immediate feedback, while traditional problems assess synthesis and design capabilities. Students receive timely correction of errors through the zyBook while developing the documentation skills needed for professional practice.

The immediate feedback proves particularly valuable for conceptual errors. A student who misunderstands a concept receives correction immediately, preventing a week of practicing incorrect methods before homework is returned.

Impact on Student Confidence

Research from engineering courses using zyBooks indicates benefits beyond improving their grades. Students report that the system helps them work through problems when stuck, improves their problem-solving confidence, and helps them connect classroom learning to applications.

This increased confidence matters for persistence in engineering programs. When students can reattempt problems with new values after viewing solutions, they learn that initial errors are part of learning rather than indicators of inability.

Getting Started: Your Action Plan

The data supports clear implementation guidelines. Success requires assigning activities for at least 5% of the course grade and restructuring class time to build on pre-class preparation.

Implementation Timeline

Week 1: Setup

☐ Configure course with 5% grade allocation and weekly or bi-weekly assignments

☐ Set up the zyBook to match your course outline

☐ Demonstrate system navigation

☐ Assign initial activities

Week 2: Routine Development

☐ Review analytics before classes

☐ Implement group challenge activity

Week 3+: Refinement

☐ Monitor completion rates

☐ Adjust plan for class-time based on data

Instructor Feedback

Early reviewers rate zyBooks as beneficial in:

- Reduced grading burden for routine problems

- Improved student preparation for class

- Better engagement with complex topics

Effectiveness ratings from instructors reviewing the Groover zyBook:

- Reading completion before class: 75% report improvement

- Student engagement: 100% report improvement

- Concept understanding: 100% report improvement

- System usability: 87% rate as user-friendly

Implementation Summary

Core Requirements:

- Grade allocation: Minimum 5% for zyBook activities

- Pre-class work: Readings and animations before lecture

- Active learning: Randomized problems for group work

Documented Outcomes:

- Increased engagement (5x improvement)

- Increased self-efficacy(confidence) in succeeding in the course and in solving engineering problems

- More effective use of class time

- Improved student confidence

The Groover zyBook provides 184 animations that reveal internal processes and continuous operations in manufacturing. Research demonstrates significant improvements in student outcomes when properly implemented. This guide provides the practical framework for achieving these results in your course.